MACHINERY

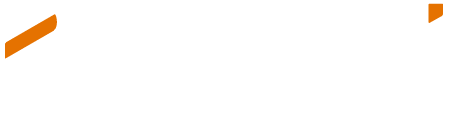

The process of injection moulding of plastics consists of taking the thermoplastic material to a “paste-like” state by “heating” it in a special cylinder, after which it is injected into a cut-out (mould). Once cooled, the material is extracted from the mould having taken it’s shape.

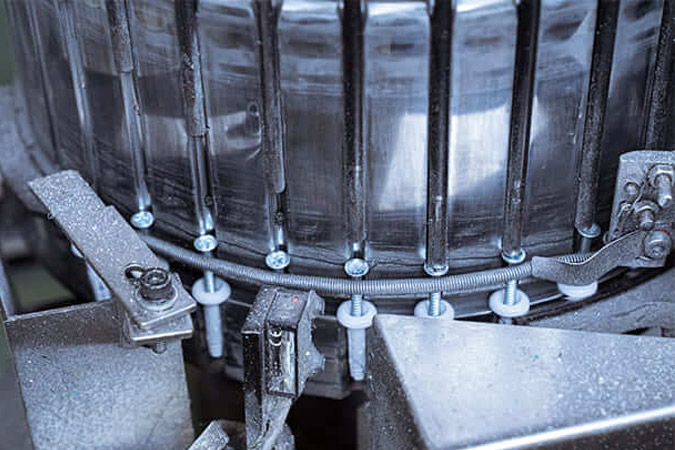

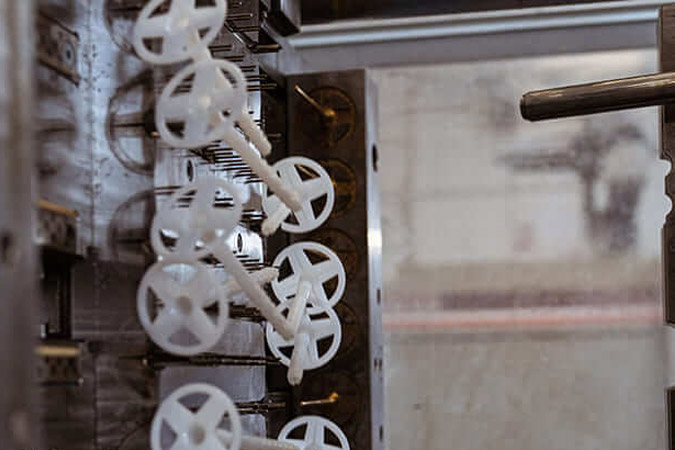

Today, Bartolucci’s fleet of machinery is comprised of 17 injection moulding machines with a clamping force of between 25 and 370 tons, and 19 CNC robots, along with an ample pool of auxiliary equipment necessary to the preparation of polymers, processing and secondary treatments.

We also have in-house welding and ultrasound facilities, a department dedicated to the assembly of more complex components, and a department for the assembly of fixings.